Guangri Electronic Machinery Co., Ltd: Leading the Way in Precision Winding Technology

Introduction

When you think about the inner workings of high-tech devices, from life-saving medical equipment to aerospace technology, the precision of the components is critical. But have you ever paused to consider how these tiny, precise components are manufactured? At the heart of many of these innovations is precision winding technology, a process that is both art and science. One of the leading companies in this field is Guangri Electronic Machinery Co., Ltd. This winding machine manufacturer has become a cornerstone in industries that demand nothing less than perfection. But what makes Guangri stand out, and why should industries rely on their technology? Let’s dive deeply into the world of precision winding and see how Guangri is leading the charge.

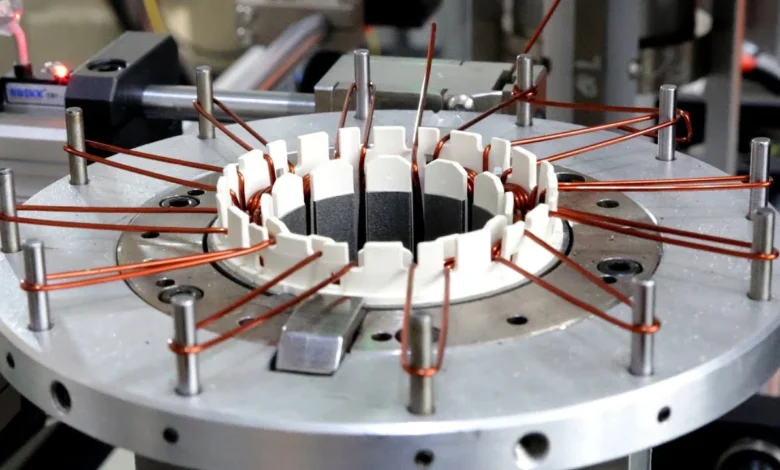

The Critical Role of Precision Winding

Precision winding is a cornerstone of modern manufacturing, especially in sectors where accuracy and reliability are paramount. Imagine a spacecraft where every wire needs to be perfectly aligned to ensure the system’s overall functionality. Or consider a medical device that must operate flawlessly within the human body. These scenarios illustrate the critical importance of precision winding. It’s not just about coiling wires—it’s about ensuring that each coil is perfectly formed to meet strict industry standards. The slightest deviation can lead to failure, which in industries like aerospace and medical, can have dire consequences. Guangri Electronic Machinery Co., Ltd understands these stakes and has developed winding machines that meet these rigorous demands.

How Guangri Supports the Aerospace Industry

The aerospace industry operates under the mantra of “zero tolerance for error.” Every component used in an aircraft or spacecraft must be perfect. This includes the wires and coils that are integral to the vehicle’s electrical systems. Guangri’s winding machines are specifically designed to handle these high-stakes applications. These machines ensure that the winding process is precise and consistent, meeting the exacting standards of the aerospace industry. Whether it’s wiring for a satellite or components for a fighter jet, Guangri’s machines deliver the reliability that aerospace manufacturers depend on. The technology behind these machines is built to withstand the demands of the aerospace environment, where even a minor flaw could lead to catastrophic failure.

Precision in Medical Device Manufacturing

In the medical field, the margin for error is even slimmer. Devices like pacemakers, defibrillators, and various diagnostic equipment must be built to the highest standards of precision. The coils and wires inside these devices need to be flawlessly wound to ensure that the devices function correctly inside the human body. Guangri’s winding machines are engineered to meet these stringent requirements. They produce coils that are consistent in size, shape, and performance, ensuring that the medical devices they are used in will work reliably. This level of precision is vital for patient safety, making Guangri’s technology an essential component of the medical manufacturing process.

Meeting the Demands of Energy Storage

As the world transitions to renewable energy sources, the need for efficient energy storage solutions is growing. Energy storage systems, such as batteries, rely heavily on precision-wound components. The efficiency and longevity of these systems depend on the quality of the winding process. Guangri’s machines are designed to produce the high-quality windings needed for these energy storage solutions. Whether it’s for electric vehicles, solar power systems, or large-scale energy storage, Guangri’s technology ensures that the components are built to last. This not only enhances the efficiency of the energy storage systems but also reduces the cost over time by extending the life of the components.

The Evolution of Winding Technology

Winding technology has evolved significantly over the years. In the past, winding was a manual process, requiring skilled operators to ensure that each coil was correctly formed. However, as the demand for precision has increased, so has the need for automated winding solutions. Guangri has been at the forefront of this evolution, developing advanced winding machines that combine automation with precision. These machines have not only improved the accuracy of the winding process but have also increased production speed, allowing manufacturers to meet the growing demand for precision-wound components. The evolution of winding technology has been driven by the need for greater efficiency and accuracy, and Guangri has been a key player in this transformation.

Advanced Winding Techniques by Guangri

Guangri employs a variety of advanced winding techniques to meet the specific needs of different industries. For example, they use tight tolerance winding for applications that require extreme precision, such as aerospace and medical devices. They also offer complex coil designs for industries like energy storage, where the performance of the winding is critical to the overall efficiency of the system. These advanced techniques ensure that Guangri’s machines can produce windings that meet the highest standards of quality and performance. The company’s commitment to innovation is evident in their continuous development of new winding techniques that push the boundaries of what is possible in precision manufacturing.

Industry-Specific Applications of Guangri’s Machines

One of the key strengths of Guangri’s winding machines is their versatility. These machines can be customized to meet the specific requirements of different industries. For example, in the aerospace industry, Guangri’s machines can produce windings that are designed to withstand high temperatures and extreme environmental conditions. In the medical field, their machines can create micro-sized coils that are used in devices implanted in the human body. In the energy storage sector, Guangri’s machines produce windings that enhance the efficiency and longevity of batteries. This ability to tailor their machines to the needs of different industries makes Guangri a valuable partner for manufacturers in a wide range of sectors.

Innovation in Machinery Design at Guangri

Innovation is at the heart of Guangri’s success. The company is constantly refining its machinery design to enhance performance, reduce waste, and increase efficiency. For example, Guangri’s machines are designed with advanced control systems that ensure the winding process is consistent and precise. These control systems monitor the winding process in real-time, making adjustments as needed to maintain the highest level of accuracy. Additionally, Guangri’s machines are built with durable materials that ensure they can operate reliably in demanding environments. This focus on innovation ensures that Guangri’s machines are always at the cutting edge of winding technology, providing their clients with the best possible solutions.

Quality Control: Guangri’s Commitment to Excellence

Quality control is a top priority at Guangri. The company has implemented rigorous testing and quality control processes to ensure that every machine they produce meets the highest standards of precision and durability. Each machine is tested extensively before it leaves the factory, and Guangri’s quality control team is constantly monitoring the production process to identify and address any potential issues. This commitment to quality ensures that Guangri’s machines deliver consistent, reliable performance, giving manufacturers the confidence they need to rely on these machines for their most critical applications.

The Future of Winding Technology

The future of winding technology is exciting, with new innovations in materials, techniques, and machinery design on the horizon. Guangri is at the forefront of this future, with ongoing research and development efforts focused on creating even more advanced winding solutions. For example, the company is exploring new materials that could enhance the performance of windings in high-stress environments. They are also developing new machinery designs that could further increase the precision and efficiency of the winding process. As industries continue to evolve and new applications for precision winding emerge, Guangri is well-positioned to meet these challenges and lead the way in the future of winding technology.

Why Guangri is the Preferred Choice

Choosing Guangri means choosing a partner that is committed to excellence in every aspect of their business. Their precision winding machines are not just tools; they are the result of decades of experience, innovation, and dedication to quality. Whether you’re in the aerospace, medical, or energy storage industry, Guangri offers the expertise and technology you need to succeed. Their machines are designed to meet the specific needs of your industry, and their commitment to quality ensures that these machines will deliver consistent, reliable performance. With Guangri, you’re not just getting a machine—you’re getting a partner that is dedicated to helping you achieve your goals.